Downloads

- Documentation

- Photometry

Features

The BWG400 is a recessed wall graze luminaire with a 3” wide aperture. The visually quiet fixture integrates with typical hard and grid ceiling systems. An optically engineered extruded aluminum reflector with proprietary micro finish anodized coating and internal shielding produce a very narrow asymmetric distribution, specifically optimized for grazing adjacent surfaces.

Performance

- Nominal Length: 4'

- Output: L: low | R: regular | H: high

- Lumens/ft.: L: 370 | R: 505 | H: 765

- Watts/ft.: L: 5.0 | R: 7.0 | H: 11.3

- Luminaire Lumens: L: 1503 | R: 2046 | H: 3107

- Efficacy (LPW): L: 74 | R: 72 | H: 67

Note: All data reflects fixtures with 3500K LEDs

Specifications

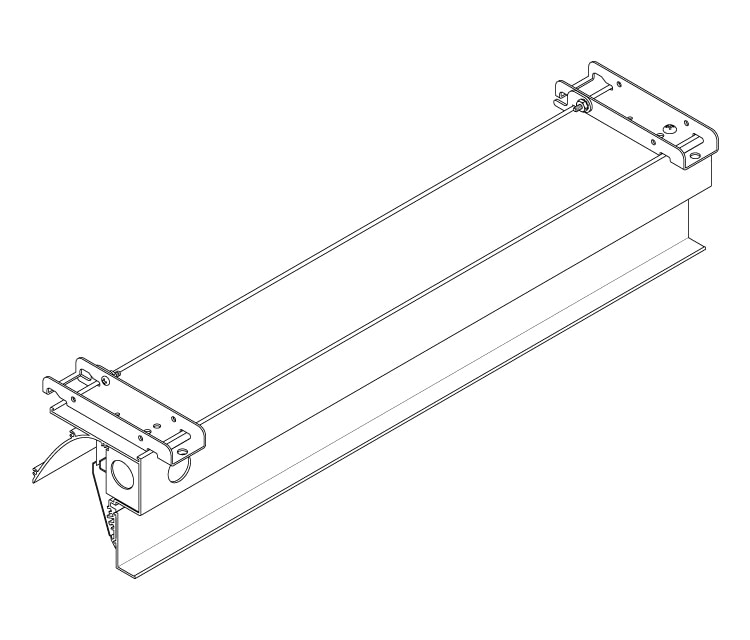

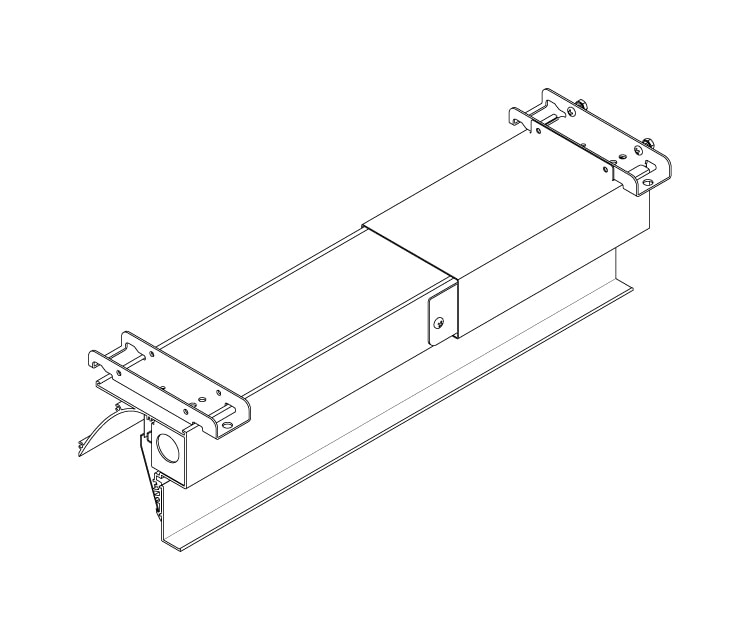

Fixture housing and trim elements made of extruded aluminum and sheet steel and aluminum parts

An optically designed extruded aluminum reflector with proprietary anodized finish and laser cut shielding components work to produce a very narrow asymmetric distribution

Available for installation in typical 9/16” and 15/16” grid ceilings or drywall ceilings with flange and trimless options

Heavy gauge, steel brackets lock fixture housing to included j-rail mounting channel

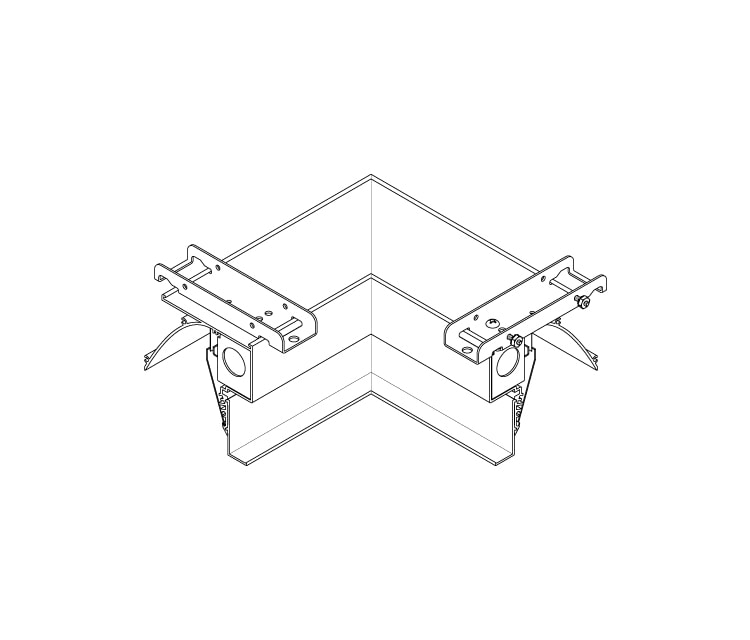

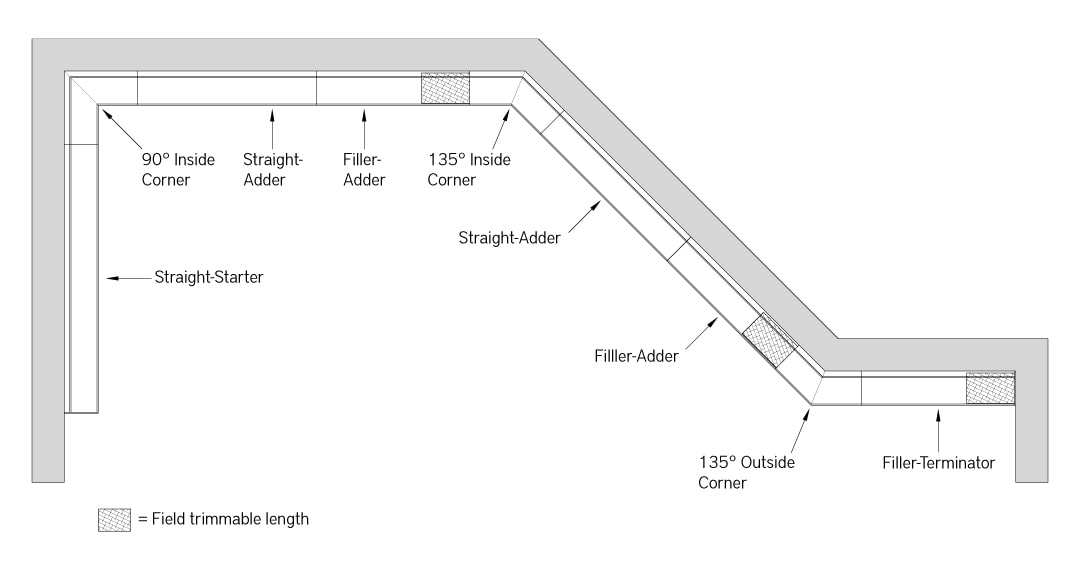

Fixtures available in straight lengths of nominal 2’–8’, 90° or 135° inside and outside corners and two field-trimmable filler units

Basic continuous run fixtures provided with 18 ga. wiring harness for 6 Amp maximum load (consult factory for runs requiring greater amperage)

Standard integral 120-277V driver offered with 0-10V dimming or non-dim (other dimming driver options available)

Integral 120-277V emergency battery backup available for 48” or 96” fixtures (supplied with remote test switch/indicator plate assembly)

Standard light outputs are 370, 505 or 765 lumens per foot

LEDs available in 2700K, 3000K, 3500K, and 4000K, within a 3 step MacAdam ellipse, all with 90+ CRI typical

Life: 50,000 hours L70

Chicago plenum rated option available

Nominal weight is 2.1 lbs. per foot

Limited five year warranty

UL and C-UL listed for dry and damp locations

IBEW manufactured and assembled

Made in U.S.A.

Product Data

Correlated Color Temperature

- 27: 2700K-90+ CRI

- 30: 3000K-90+ CRI

- 35: 3500K-90+ CRI

- 40: 4000K-90+ CRI

Driver

- ND: non-dimming

- D: 0-10V, 1%

- DTR: triac, 1%, (120V ONLY)

- DLV: electronic low voltage, 1%, (120V ONLY)

- HES: Lutron EcoSystem, soft-on/fade-to-black, 1%

- EL: eldoLED ECOdrive, 0-10V, 1%

- ES: eldoLED SOLOdrive 0-10V, 0.1%

- ELD: eldoLED ECOdrive DALI, 1%

- ESD: eldoLED SOLOdrive DALI, 0.1%

Mounting

- T1: t-grid 9/16"

- T2: t-grid 15/16"

- FT: flange trim

- TL: trimless

- CF: consult factory for custom mounting

Light Output

(lumens per foot)

- L: low – 370

- R: regular – 505

- H: high – 765

- CF: consult factory for custom output

Run Configuration

Run configuration applicable to Straight and Filler shapes. Corners are always adders.

- SN: single

- ST: starter

- AD: adder

- TR: terminator

Options

- CP: Chicago plenum (Not available for F1 or F2 filler fixtures)

- ED: emergency driver (48" or 96" non-dim or 0-10V only)

Shape

- 22: straight 22-1/4"

- 33: straight 33-1/4"

- 44: straight 44-1/4"

- 55: straight 55-1/4"

- 66: straight 66-1/4"

- 77: straight 77-1/4"

- 88: straight 88-1/4"

- F1: Filler 12-1/4" – 17-3/4"

- F2: Filler 17-3/4” – 23-1/4”

- CI90: corner inside – 90°

- CO90: corner outside – 90°

- CI135: corner inside – 135°

- CO135: corner outside – 135°

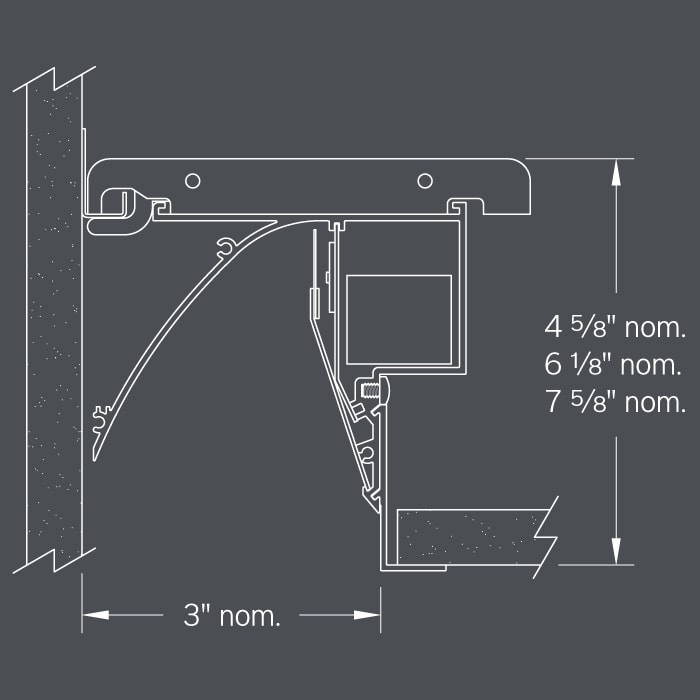

Mount Depth

- A: refer to table

- B: refer to table

- C: refer to table

Section

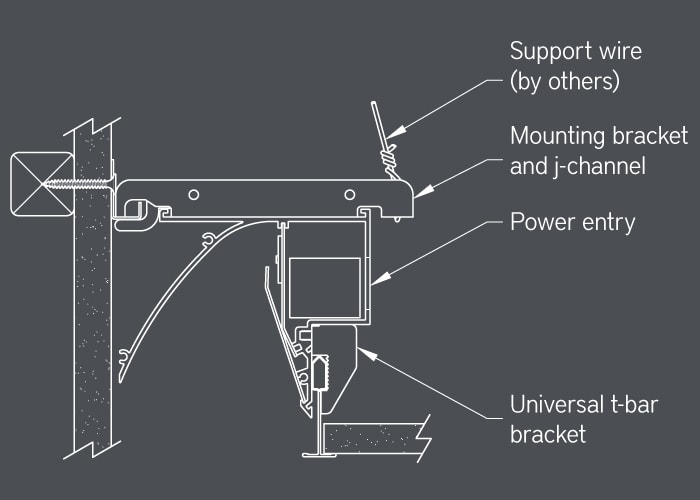

Mounting Options

- Fixtures interface with common flat, regular and slotted t-grid types

- A clasp feature locks the top bracket to provided heavy gauge j-channel, mounted to wall surface

- Housing secured with support wires or ¼-20 threaded rod (by others)

Ordering Code: T1 and T2

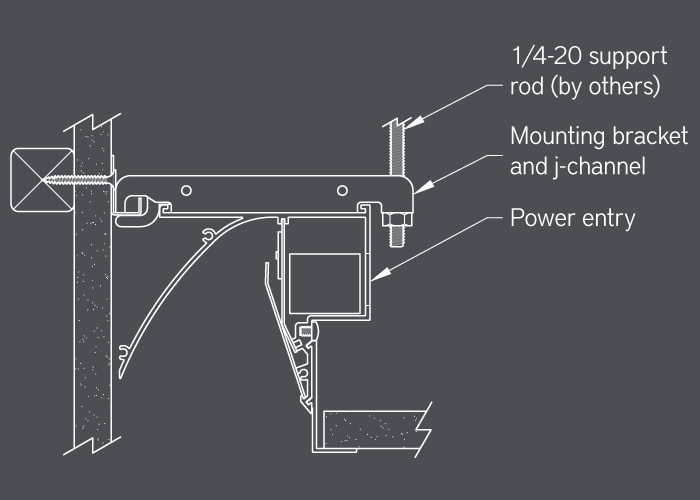

- Installs before ¹⁄₂” or ⁵⁄₈” drywall

- ¾” wide extruded aluminum trim flange in matte white finish

- A clasp feature locks the top bracket to provided heavy gauge j-channel, mounted to wall surface

- Housing secured with ¼-20 threaded rod (by others)

Ordering Code: FT

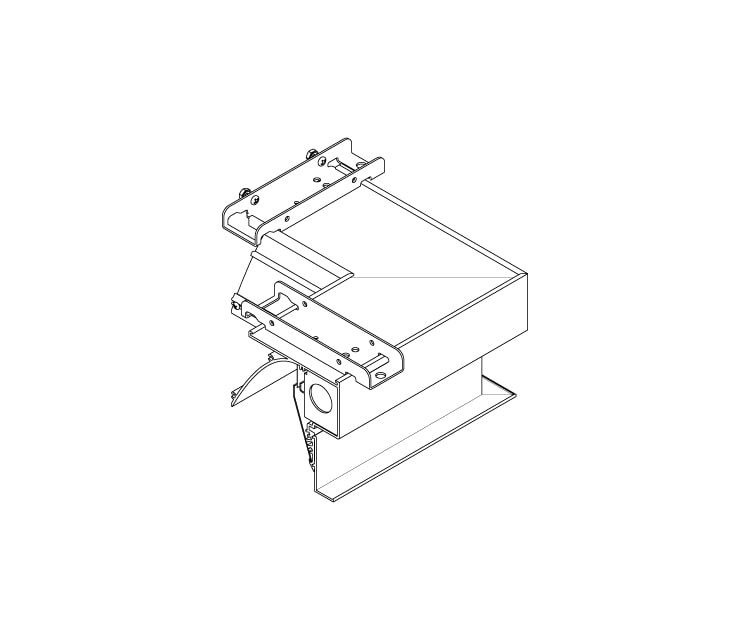

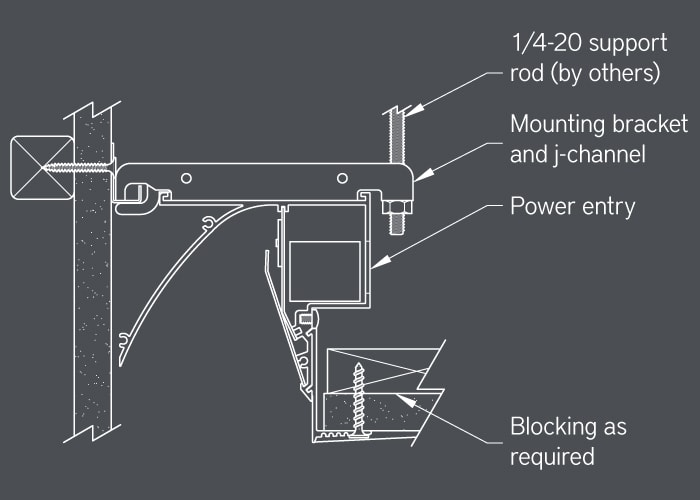

- Installs before ¹⁄₂” or ⁵⁄₈” drywall

- Top bracket locks to provided heavy gauge j-channel mounted to wall surface

- Housing secured with support wires or ¼-20 threaded rod and self-tapping drywall screws (by others) into blocking as required

Ordering Code: TL

Shape

Layout Example

After installing mounting channels around the perimeter, install the corner fixtures, followed by straight fixtures. Trim the filler fixtures to fit remaining run lengths and place onto the mounting channel.

IMPORTANT: Provide finished layout to Bartco Lighting for verification